How Industrial IoT Edge Computing Enabled This Oil and Gas Producer to Reduce Site Visits, Operating Costs, and Carbon Emission While Increasing Company Efficiencies and Site Visibility

THE PRODUCER

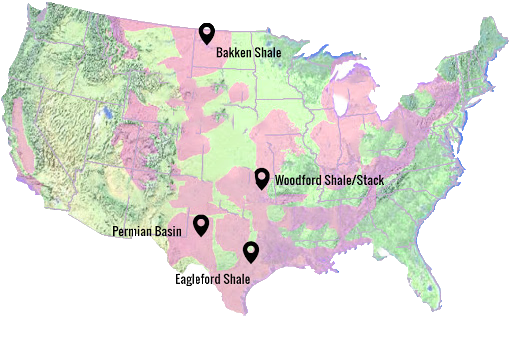

This exploration and production company is headquartered in Houston TX. They own assets in the Eagle Ford Shale in Texas, The Bakken Shale in North Dakota, the STACK and SCOOP in Oklahoma, and the Permian Basin in West Texas/New Mexico.

The producer is highly focused on safety, environment, and innovation. They continually lead their peers in sustainability and are focused on creating a brighter future for oil and gas in today’s market.

THE CHALLENGE

In efforts to reduce well site risks such as leaks and damaged equipment, which can cause safety concerns, the producer had an “every well every day” policy. An every well every day policy is exactly as it sounds; They required their site operators to visit every one of their oil wells at least once a day. While this is a great model for maintaining the producer’s high standards for safety and environmental responsibility, it was not conducive for their bottom line.

On average, each well site operator could visit 5 oil pads a day, assuming none of the wells needed maintenance. Some operators would drive to sites 2-3 hours away, check the site for 15 minutes, and then drive 2-3 hours back. This proved to be an ineffective use of resources.

Another issue was that the producer had no way of authenticating invoices from 3rd party companies that were hired to complete work on certain well sites. For example, the producer would pay a water tanker truck to empty well pad tanks multiple times a week. The tank truck company, knowing there was no way of proving how many times they were on site, could invoice for more site visits then they actually completed.

The producer was losing money because of process inefficiencies and the inability to audit 3rd party invoices. They recognized this issue and set out to find an innovative way to remediate the issue without compromising their every well everyday policy.

Another issue was that the producers Carbon Footprint from the daily truck runs were proving to be quite high. Each truck emitted ~219lbs of Co2 a day. Because of the producer every site everyday policy, each truck emitted ~79,935lbs of Co2 each year.

THE SOLUTION

Twin Eagle was hired by the producer to install its Industrial IoT edge computing platform to utilize it’s Field Vision solution. Field Vision was designed to increase efficiencies and allow it’s end user to have more oversite of their assets

Field Vision met all of the producer’s criteria and created some additional benefits as well. Twin Eagle utilized Field Vision’s remote monitoring option (Remote Vision) that utilized an Industrial IoT PTZ Camera on a movable solar powered skid. Remote Vision is capable of monitoring all assets on the well site and capturing all key metrics important to the producer. In addition to Remote Vision, we also installed the Field Vision option, Intelligent Vision. This made it possible to track vehicles and personnel that came onto the site.

Twin Eagle was able to program Intelligent Vision so that it recorded specified events and stored them in The Industrial IoT OSM (Optical Sensor Management) for someone to view later. For example, the camera would count, record, historize and report data locally every time a tank truck would enter the site. This allowed the producer to audit the invoice from the tank truck company to confirm they were billing for the correct amount of site visits.

The Industrial IoT solution was designed with a focus on ease of use. Twin Eagle wanted to ensure that the producer could easily adopt this solution into the producer’s processes.

Below is the important information for this solution.

SOLUTION SPECS

– 1 time purchase fee (no reoccurring monthly fees)

– Solar powered

– 3 days of autonomy on a full charge

– Custom integration into existing networks (This example is LTE communications)

– Movable design

– Easy to move if needed at another site or if site is sold.

– Custom preset tours of well sites

– This makes a site survey as easy as 1 click

– Event tracking

– Programmable to watch for specific events and record when event is triggered.

– Mobile phone and desktop accessibility

THE RESULTS

Site Visits

Using Remote Vision, the producer was able to reduce the amount of site visits by 70%-80% while increasing the site visibility of each well site.

Reduction in Carbon Emissions

Because of the 70%-80% reduction in site visits, the producer was able to reduce carbon emissions by 4,480lbs per month for every truck in their fleet that was performing the daily truck runs.

Increased Oversite

The producer was able to change its model from every well every day to every well multiple times a day. In this case, the producer asked Twin Eagle to program Remote Vision to run 2 site surveys a day and send the images of key metrics to the operator through the Industrial IoT OSM.

Decreased Emergency Response Time

The producer was able to reduce their response time to emergencies because Intelligent Vision would alert on abnormalities and the end user was able to view the site whenever they needed to. In the past they would have to wait until someone came on the site before they noticed an emergency.

Invoice Auditing

Using Intelligent Vision, the producer was able to eliminate invoice discrepancies from 3rd party companies because Intelligent Vision was able to recognize when a tanker truck entered the site. It then historized the data for the producer to review when they received the invoice.

Reduced Operating Cost

The producer was able to reduce its operating cost because they were able to optimize their employees time and focus only on the sites that needed maintenance. They were also able to cut out inaccurate invoices which would result in over billing.

Other Benefits

– Tank level monitoring with thermal cameras

– The producer was able to check for PPE on its employees and contractors.

CONCLUSION

Twin Eagle was able to provide this producer with an Industrial IoT Solution that allowed them to maintain their standard for well site inspections and safety all while reducing their operating cost and increasing their efficiencies. The producer was also able to reduce their carbon footprint substantially through reducing the amount of truck runs they were performing. The producer was able to audit invoices from 3rd party contractors with Intelligent Vision.

Twin Eagle went above and beyond the producer’s criteria with its Industrial IoT solution. It did not need an external power source, it could be integrated into their existing networks, it can be easily moved from site to site, and it would be easily managed from a desktop or mobile phone. Twin Eagle also provided the producer with a solution that did not need a monthly reoccurring fee to maintain, lowering operating costs and improving ROI. After programming the camera and configuring the communications devices on the skid, Industrial IoT was plug-and-play for the producer.

SET UP YOUR DEMO

Industrial IoT is available for demo using Twin Eagle’s Mobile Applications Platform.