Historically, manual operations and visual inspections by Upstream and Midstream personnel have been used to detect and report visible emissions, such as liquid leaks, flares and volatile organic compounds (VOC). As noted in recent blog posts and case studies, this can be an inefficient use of resources given the cost of sending personnel to multiple remote locations; it is, unfortunately, also prone to human error.

The Industrial IoT OT platform can automate these types of inspections by using intelligent cameras and machine learning to capture actual events and filter out environmental conditions (rain, mist, haze, etc) that ordinarily would have required human observation to determine. That allows field personnel to react quickly to verified events and cover all sites accurately and efficiently.

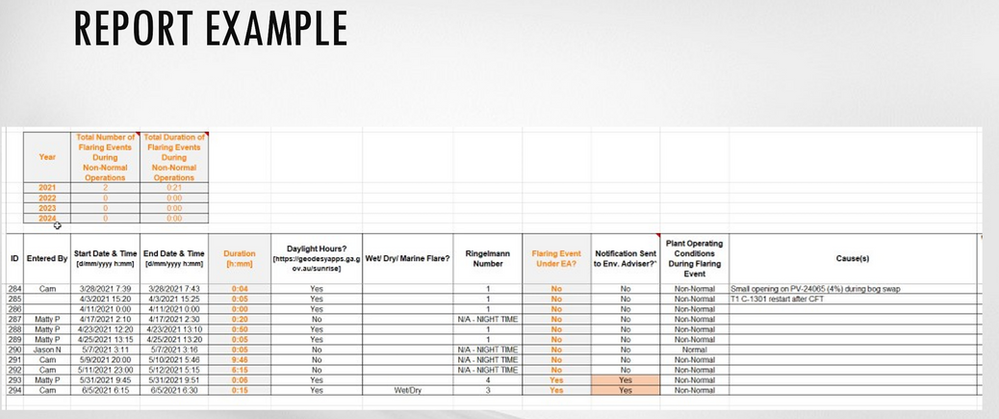

Even better, Industrial IoT OT simplifies and automates mandatory EPA reporting. Instead of interpreting and transcribing field notes and manually submitting to the EPA, Industrial IoT provides metadata for accurate and automated reporting. This has a number of downline advantages, including:

- Expedites pending permit applications based on Method 9 and Method 22 observations as they won’t be bogged down by manual recording and time required to perform necessary tests.

- Improves frequency, timeliness, quality, and accuracy of reporting as opposed to the traditional “eyeball” method of reporting.

- Allows accurate recording and reporting on the qualitative and quantitative elements of both Method 9 and Method 22 reporting

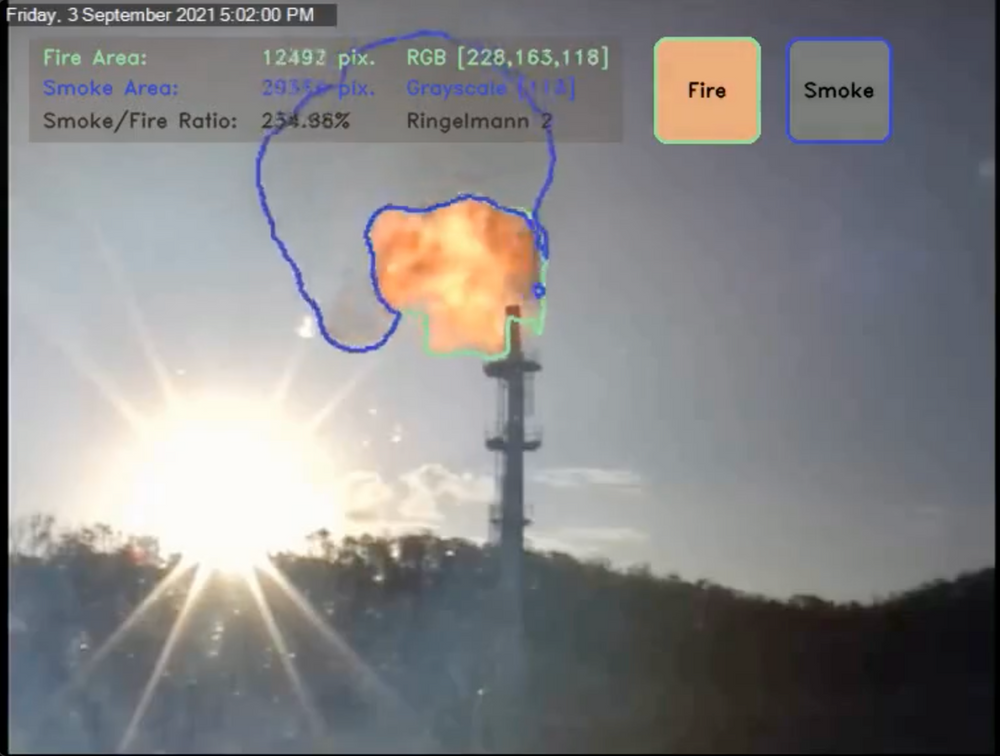

Using cameras and the Industrial IoT OT machine learning platform, the system proactively detects and alerts operators to emissions events and is able to accurately quantify the level of those emissions. All in real-time via MQTT – the standard messaging protocol for the Internet of Things (IoT) – and other IoT communication protocols.

Operators can define their report parameters within the system and reporting on the following elements up to 4 times per second:

Industrial IoT OT report example:

Watch Industrial IoT OT in action.

In a time when OGE is committed to environmental stewardship and under pressure to do more with less, Industrial IoT OT is empowering the digital oilfield and helping the industry deliver quality products safely, efficiently, and economically. Find out how, and schedule your demo today.